Biogas Plants – environmentally friendly operation with Sager + Mack pumps and filters

Clean, ecological and sustainable energy is in the context of our time. Biogas plants play an important role in the energy mix. However, the generation of environmentally friendly electricity through biogas can pollute the environment through various processes. The fermentation processes and the use of treatment or waste gas purification systems produce waste water that is contaminated with ammonia or sulfuric acid. Both are substances that should not be released into the atmosphere. The right equipment is required to manage these processes responsibly and safely.

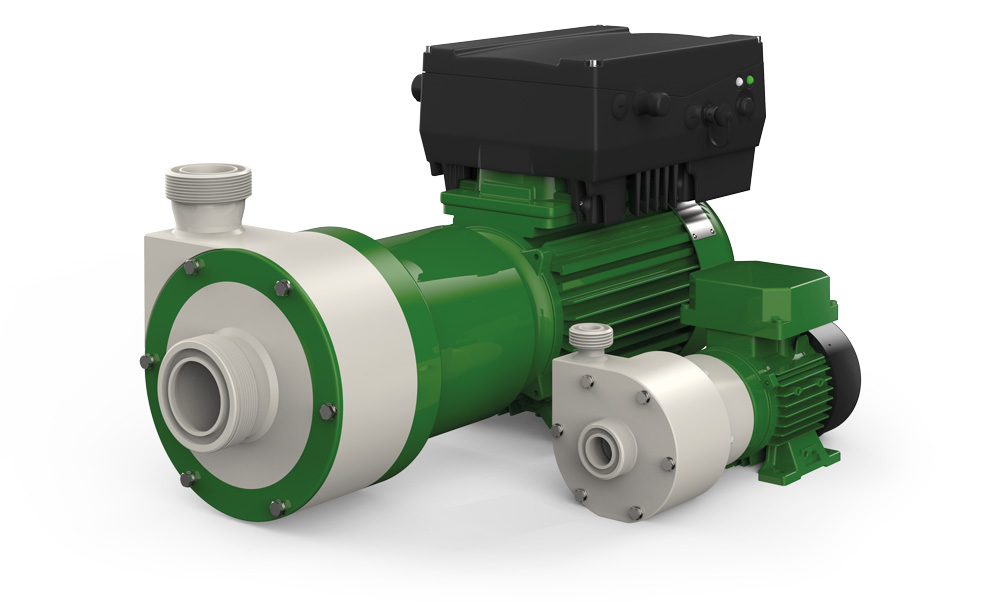

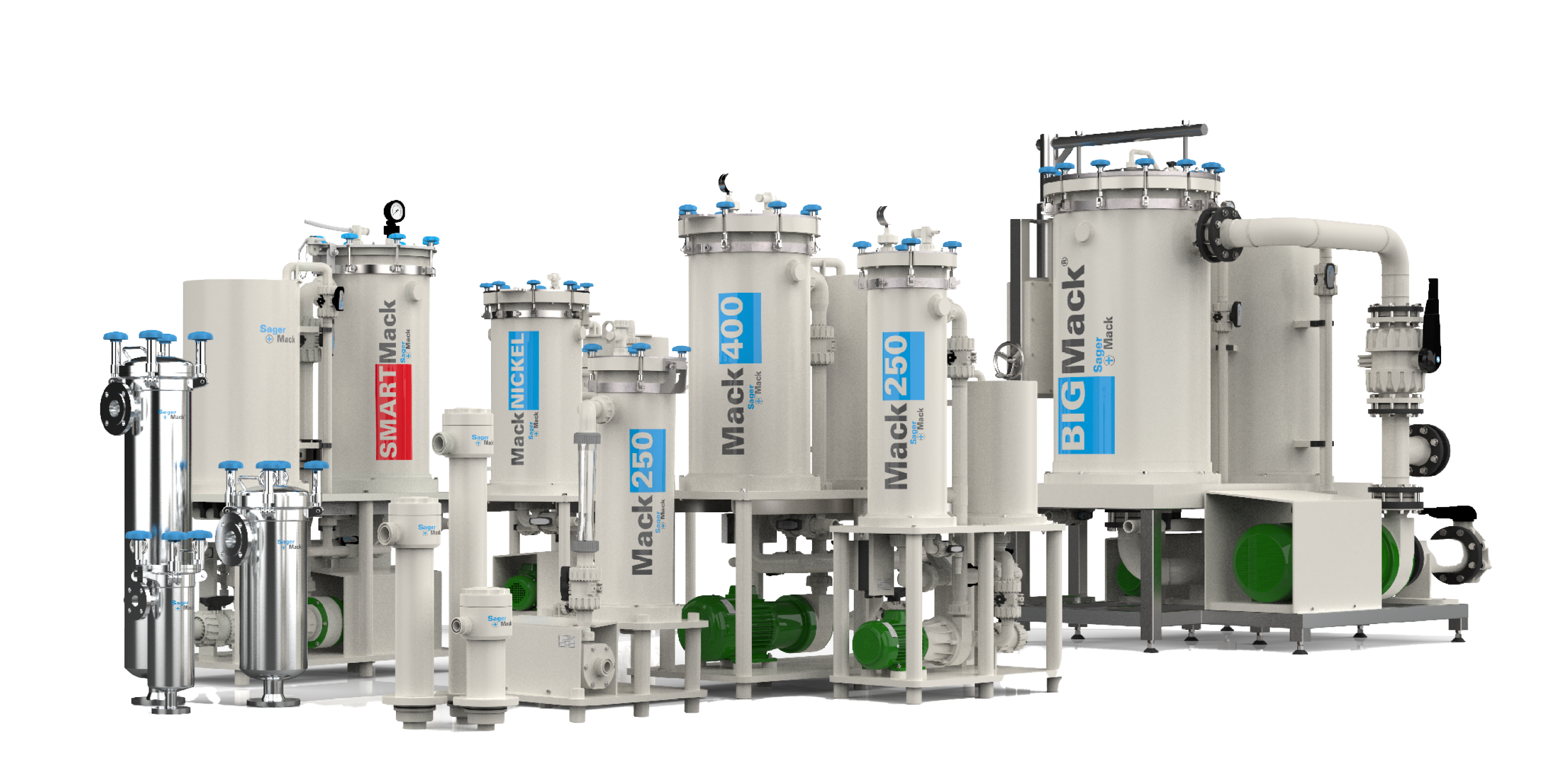

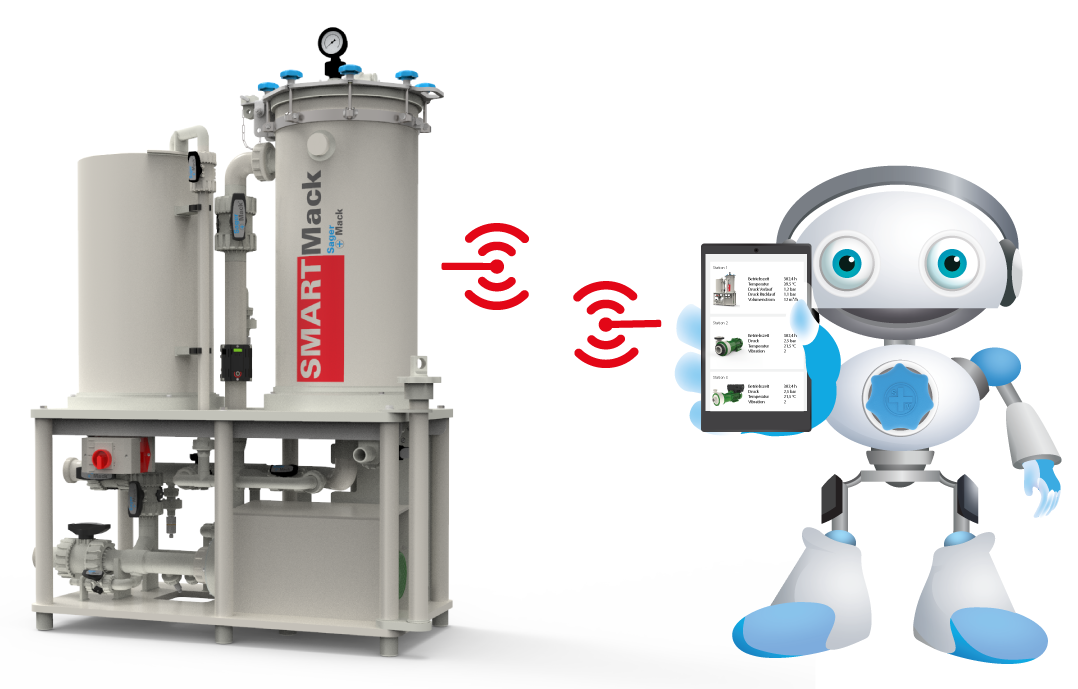

SAGER+MACK pumps and filter technologies, due to their robust design, enable low-maintenance and reliable operation, free of unwanted leakages. This prevents emissions to air or soil. Sager + Mack offers complete solutions from a single source – from the individual pump or filter unit to filter stations in modular design including the appropriate filter media, we can offer a wide range to operators of biogas plants, as well as plant constructors for flue gas desulfurization plants. Our pumps reliably convey aggressive, corrosive as well as chemically contaminated liquids.