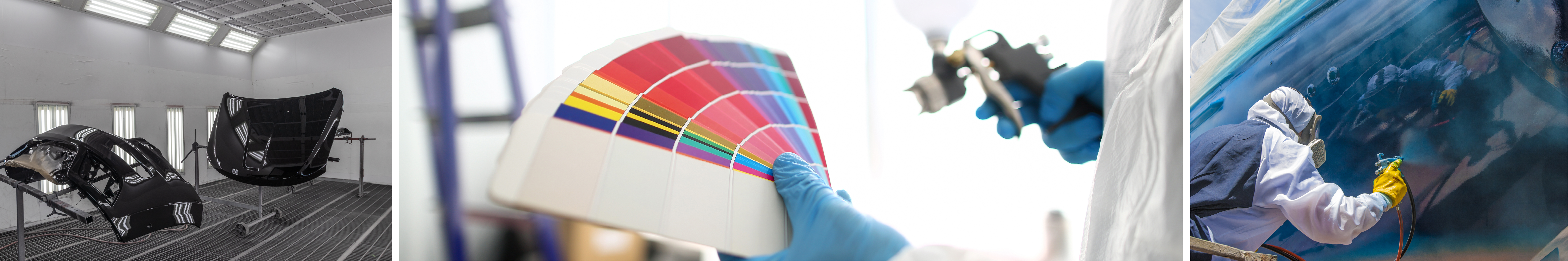

Pumps and filters for paint production

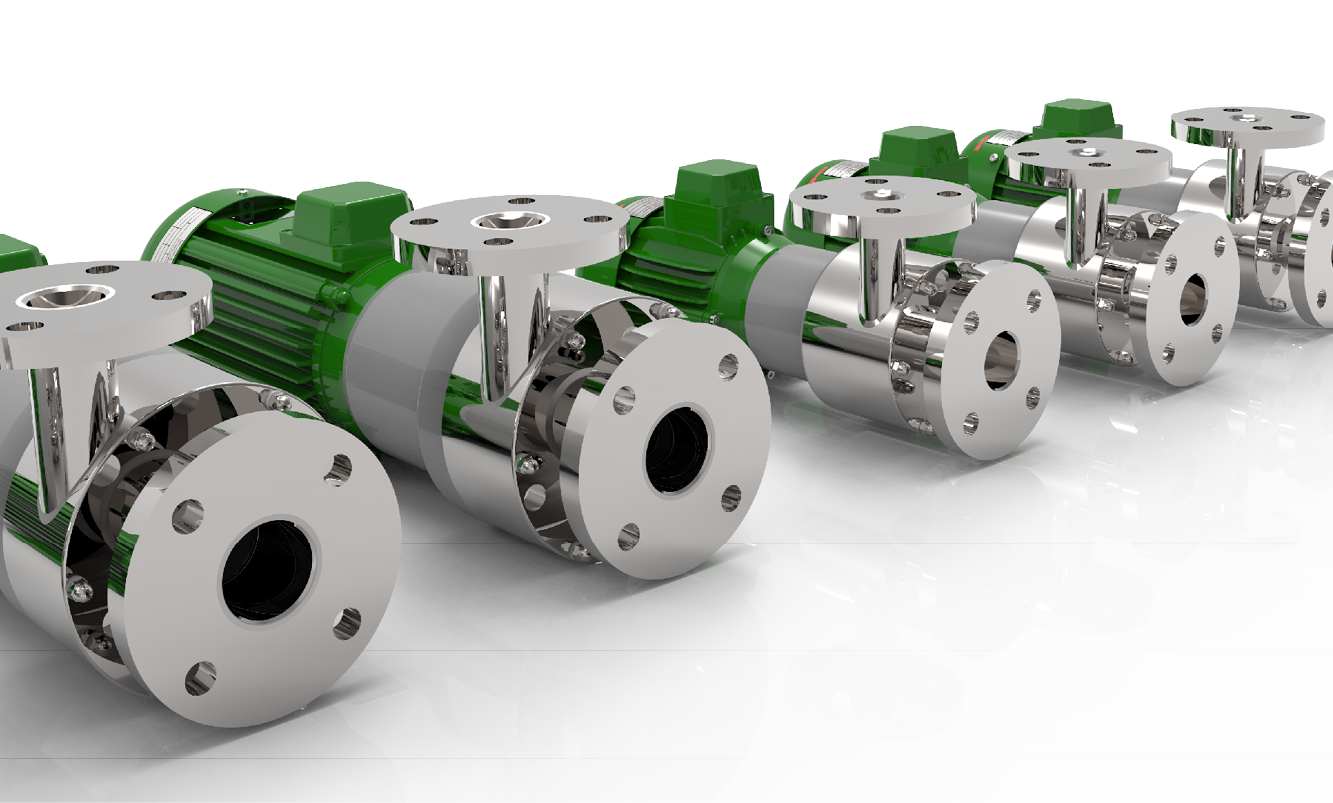

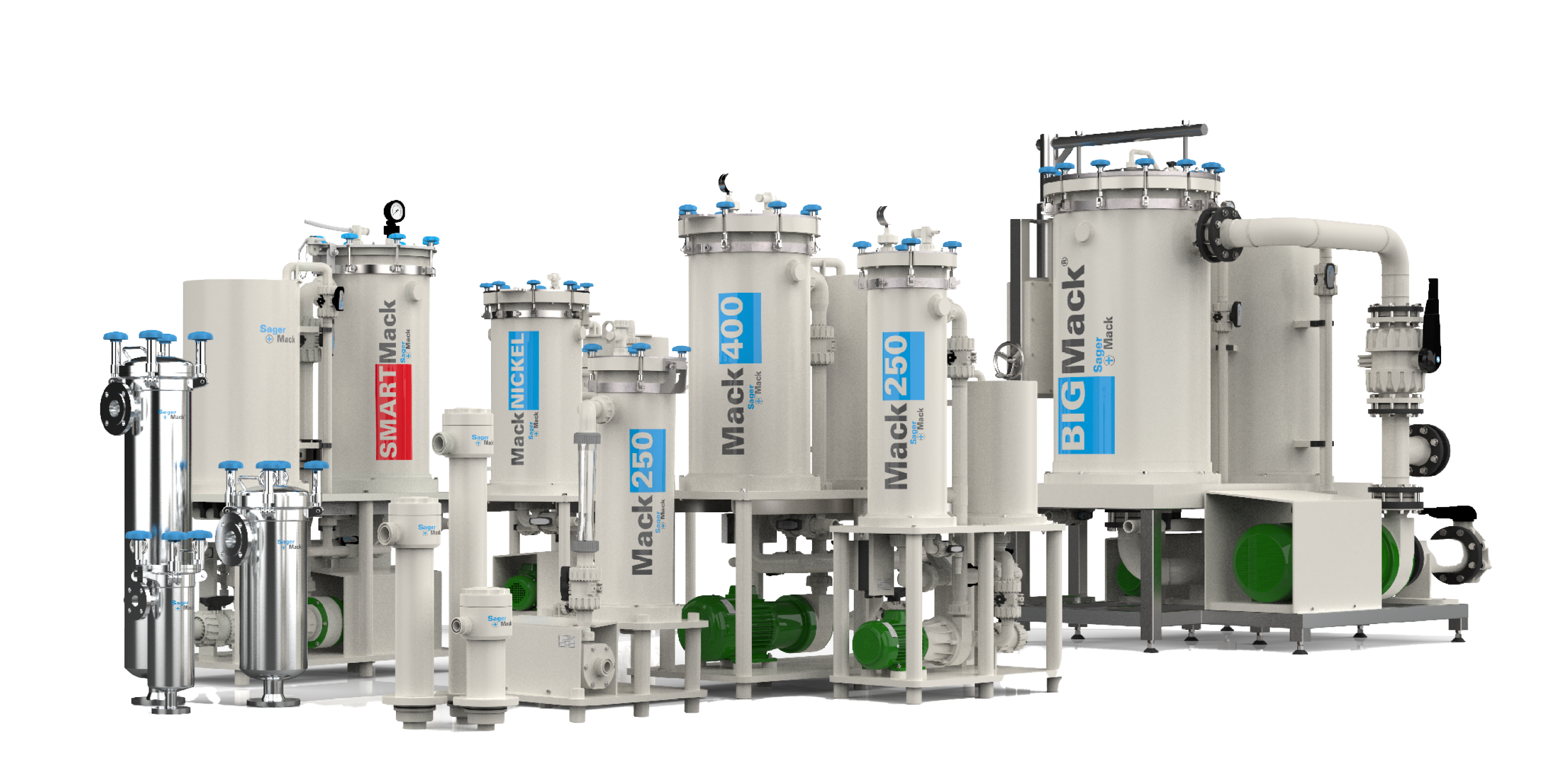

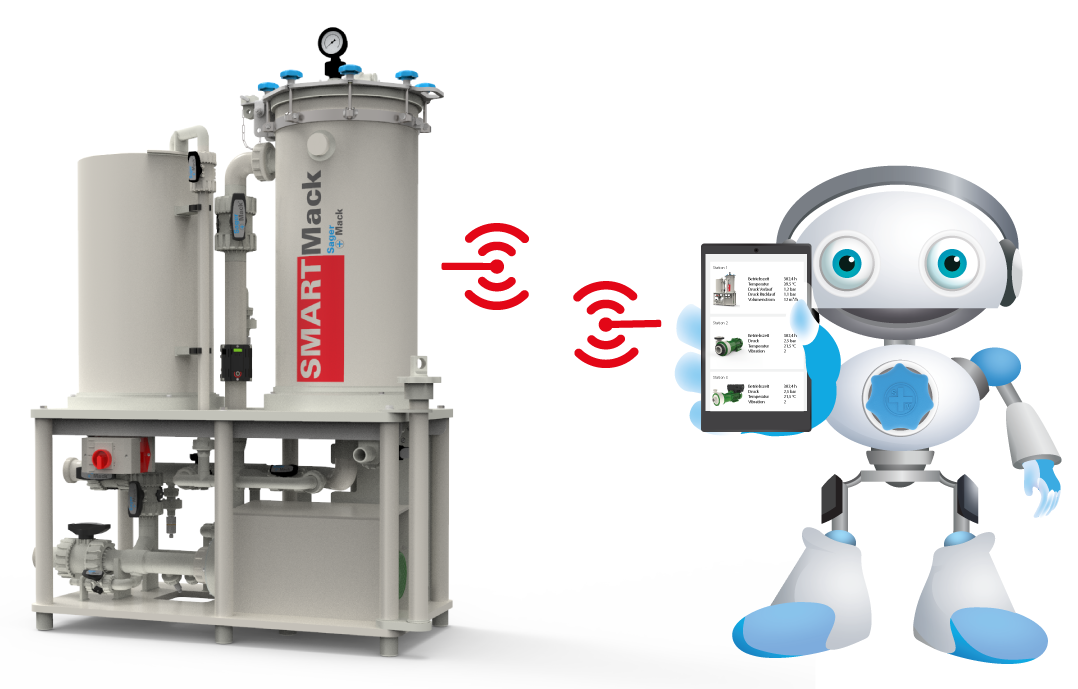

Sager + Mack supplies you with chemical-resistant products from one single source. Many applications in the paint and coatings industry are very demanding. Temperature-sensitive media can be easily handled with the magnetic driven pumps from Sager + Mack. Sager + Mack pumps can be used to convey explosive, highly aggressive or hazardous substances in paint production.

Even in the upstream and downstream process technology, contaminated, water-polluting substances are not a challenge. The TA-Air-compliant design of the magnetic driven pumps reduce the potential risk to employees and system technology.